Testo 312-4 Manometer 200hPa 0632 0327

- Backlit LCD Display

- Printer Output

- Resolution 0.01 hPa

- RS232 Interface

- Manufacturer Certificate Included

- Data Logging

- Absolute Pressure Module

- Differential pressure module

-

-

Information on the calibration of newly purchased equipment and what it means to you.

Calibration and its certification comes in varying forms on new equipment and in this section, we will break it down into the three areas that we use to classify calibration state at the point of purchase.

Manufacturers Calibration Certificate

This is a calibration certificate offered by the manufacturer supplied with the tester. This is also known as an end-of-line certificate or manufacturer’s certificate. These certificates vary depending on the manufacturer and product. They will not have your company's name on them and don’t always show proven test results.

Where applicable we will include the following statement relating to the item/s on the products page under the heading *Important Calibration Information.

This instrument comes complete with the manufacturer's calibration certificate. Please be aware that these certificates are generic and may also be time-lapsed.

If you would prefer a personalised full traceable calibration certificate applied to the equipment before dispatch, then please select this option from the drop-down menu above, an additional calibration charge will apply.Manufacturers Certificate of Conformity

A manufacturer's certificate of conformity is not a calibration certificate. It is merely a statement that the equipment has been produced to operate within its intended application, it has no traceable certificate or constitutes any defined results for accuracy before leaving the manufacturing process.

Where applicable we will include the following statement relating to the item/s on the products page under the heading *Important Calibration Information.

This instrument comes with a ‘manufacturer's certificate of conformity’. It is important to understand that this does NOT constitute a ‘calibration certificate’. A certificate of conformity merely states that the equipment has been designed and produced to meet the requirements of its intended application.

Where calibration of an instrument is possible we will offer this as a separately purchasable item and may be selected from the drop-down box above. You will be sent a full traceable calibration certificate produced in our laboratory and applied with your details as required.Personalised traceable calibration certificate from isswww

This is a calibration certificate created by us at ISS. This certificate is fully traceable to national and international standards. The certificate will show your company's details, tester information, proven test results and the equipment used to carry out the test. Nearly 90% of all calibrations we do are done in-house in one of our many fully equipped laboratories. You can add this service to your order on the product page before you checkout.

Where applicable we will include the following statement relating to the item/s on the products page under the heading *Important Calibration Information.

We are on occasion able to offer FREE calibration on certain products at their point of sale (newly purchased equipment only) please look out for the following badge on the product's page to take advantage of this free offer.

-

-

Testo 312-4 Manometer 200hPa 0632 0327

|

TEMPORARILY UNAVAILABLE The manufacturer has advised that this item is currently unavailable with a currently unknown lead-time. We will update the listing as and when this situation changes. |

Testo 312-4 Comes Supplied With:

- Testo 312-4 differential pressure measuring instrument

- Battery

- Calibration protocol.

Overview:

A variety of directives describe the tests which have to be carried out before commissioning water and gas pipes. The testo 312-4 differential pressure measuring instrument offers measuring processes for load and tightness tests as well as serviceability tests on gas pipes using air. It also enables the checking of static gas and gas flow pressures, as well as the nozzle pressure setting on gas burners or boilers.

These measurements are possible with the testo 312-4 differential pressure measuring instrument

- Tightness and serviceability testing by pressure drop on gas pipes in accordance with DVGW TRGI 2008

- Load testing on gas pipes in accordance with DVGW-TRGI 2008 using our high-pressure probe (can be ordered as an option)

- Pressure testing on drinking water pipes using water and with the support of the optional high-pressure probe in accordance with DIN 1988 (TRWI) and using air in accordance with the ZVSHK information sheet

- Pressure testing on waste water pipes using our high-pressure probe (can be ordered as an option)

- Checking the gas pressure regulator by recording the readings over a defined period (max. 25,000 readings)

- Checking the gas connection and gas flow pressure, as well as setting the nozzle pressure on gas burners and boilers

Practical features of the differential pressure measuring instrument

The testo 312-4 pressure measuring instrument offers a high level of operating convenience in order for you to carry out pressure measurement efficiently - for instance through preset measuring processes or the clear presentation of readings on the large display. The testo fast printer, which can be ordered as an extra (0554 0549), means you can produce measurement data printouts directly on site. The easyheat PC software is available to you as an option for data transfer and evaluation. Furthermore, probes which are also available for various measuring tasks can be attached to the differential pressure measuring instrument (e.g. high-pressure probe or thermocouple probe for temperature measurement).

Key Features:

-

Tightness testing and load testing on gas pipes

-

Serviceability testing with air by pressure drop on gas pipes

-

Pressure testing on drinking water and waste water pipes using air

-

Automatic recording of measuring values over several hours

Typical Applications:

Pressure measurements on burners

Checking the gas pressure on burners is one of the standard measurements during services of domestic heating systems. This involves measuring the gas flow pressure and gas resting pressure of the system. The flow pressure, also called supplied pressure, refers to the gas pressure of the flowing gas and resting pressure of the static gas. If the flow pressure for gas boilers is slightly outside the 18 to 25 mbar range, adjustments must not be made and the appliance must not be put into operation. If the burner is nevertheless put into operation, it will not be able to function properly and, when the flame is generated, small explosions will occur and ultimately malfunctions; the burner will therefore shut down and the heating system will fail.

Pressure tests on gas pipes (load test)

The technical regulation for gas installations (in short: TRGI) is a binding and at the same time important regulation for skilled tradespeople. The TRGI governs how gas installations are to be planned, designed, serviced and maintained. This applies to all gas installations. This regulation is taken care of by the German Association for Gas and Water (DVGW). The TRGI 2008 is the current version. Amongst other things, this states that gas pipes are to be tested according to the construction phase (basic shell, completion and repairs). Load testing is one of the checks that plays a role in the application stated here: in this process, the material of a gas pipe is tested for stability and the connections for service life; this takes place prior to plastering over or concealment of the gas pipes. During load testing, the newly installed pipe, without fittings or gas appliances, is put under 1 bar pressure. The testing medium is air or inert gas. There must be no pressure drop detected during the test, which lasts at least 10 minutes.

Pressure tests on water pipes

According to the legal regulations of DIN EN 806-4, DIN 1988-7 and DIN 1610, drinking and waste water pipes are to be tested for leaks before being put into service by means of a pressure test with air, inert gas or water; they are also to undergo load testing with air or inert gas. However, for reasons of hygiene, it is best if the pipes remain dry until shortly before commissioning and do not undergo a leak test using water. A pressure test with air is also recommended to prevent metallic materials from corroding. The pressure test is split into two pressure-related parts where test pressure and time depend on the objective (load or leak). Leaks can usually be heard very quickly. If it is difficult to locate the leaks, the usual auxiliary tools and materials for gas pipes are used (spraying or brushing on foaming solutions).

Pressure tests on gas pipes (leak, load test)

The technical regulation for gas installations (in short: TRGI) is a binding and at the same time important regulation for skilled tradespeople. The TRGI governs how gas installations are to be planned, designed, serviced and maintained. This applies to all gas installations. This regulation is taken care of by the German Association for Gas and Water (DVGW). The TRGI 2008 is the current version. Amongst other things, this states that gas pipes are to be tested according to the construction phase (basic shell, completion and repairs). The following checks in particular play a role in the application stated here:

Load test

In this process, the material is tested for stability and the connections for service life; this takes place prior to plastering over or concealment of the gas pipes. During load testing, the newly installed pipe, without fittings or gas appliances, is subjected to 1 bar pressure. The testing medium is air or inert gas. There must be no pressure drop detected during the test, which lasts at least 10 minutes.

Leak test

This test is for checking the pipe for leaks, with fittings and without gas appliances. The measuring instrument must not register any drop in pressure during the minimum 10-minute testing period (depending on the system volume); the test pressure is 150 mbar (previously 110 mbar).

Temperature measurements on radiators

When measuring temperatures on radiators, the flow and return temperature are recorded in particular and assessed by the tradespeople. The flow temperature is defined as the temperature of the thermal transfer medium (e.g. water) that the system is supplied with. The temperature of the medium flowing out of the system is correspondingly called the return temperature. To prevent losses within the heat distribution system and achieve a better level of efficiency, spot recording of flow and return temperatures is necessary. Implementation of relevant measures ultimately leads to hydraulic adjustment on the basis of knowledge about the flow and return temperatures. This defines a procedure with which every radiator or heating circuit of a flat radiator within a heating system is supplied at a set flow temperature with the precise amount of heat needed to achieve the ambient temperature required for the individual rooms. Flawed operating conditions will result in considerable excess consumption of electricity and heating energy. The German Energy Saving Regulation (EnEV) requires hydraulic adjustment for systems being set up or overhauled for this very reason.

Pressure tests on gas pipes (leak test with external high pressure probe, load test)

The technical regulation for gas installations (in short: TRGI) is a binding and at the same time important regulation for skilled tradespeople. The TRGI governs how gas installations are to be planned, designed, serviced and maintained. This applies to all gas installations. This regulation is taken care of by the German Association for Gas and Water (DVGW). The TRGI 2008 is the current version. Amongst other things, this states that gas pipes are to be tested according to the construction phase (basic shell, completion and repairs). The following checks in particular play a role in the application stated here:

Load test

In this process, the material is tested for stability and the connections for service life; this takes place prior to plastering over or concealment of the gas pipes. During load testing, the newly installed pipe, without fittings or gas appliances, is subjected to 1 bar pressure. The testing medium is air or inert gas. There must be no pressure drop detected during the test, which lasts at least 10 minutes.

Leak test

This test is for checking the pipe for leaks, with fittings and without gas appliances. The measuring instrument must not register any drop in pressure during the minimum 10-minute testing period (depending on the system volume); the test pressure is 150 mbar (previously 110 mbar).

ISSWWW and Testo

Testo Limited was established in 1983 as the UK subsidiary of testo and is based in Alton, Hampshire where they supply a full range of test equipment across the UK and Ireland. They are a key supplier to the Facility Management and Industrial Maintenance Sectors where they are able to provide the full range of instruments which are critical to the effective and efficient maintenance of premises, and allow compliance with all key regulations.

Testo have many innovative products to their portfolio with a modern attractive design. Aesthetic appeal isn't something usually attributed to test equipment but Testo really breaks the mould. Coupled with their pedigree as a worldwide manufacturer and supplier with a proven track record, we are confident in supplying and recommending Testo products without reservation.

| Key Features | Backlit LCD Display, Printer Output, Resolution 0.01 hPa, RS232 Interface, Manufacturer Certificate Included, Data Logging, Absolute Pressure Module, Differential pressure module | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Product Stock Status | Product is currently unavailable – Click Here for related products | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Manufacturer | Testo | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Short Description |

*Accuracy information applies only to instrument without probes connected

Updated January 2024

Please note, our cut-off time is 2:00pmOrders requiring calibrationWhilst we take the greatest care to get all orders dispatched and delivered to you in the stated time frame, orders received PM and requiring calibration may on occasion miss dispatch that day, according to the complexity of the calibration.Be assured they will ship on the next dispatch this in most cases should not add more than 24 hours to your delivery. Bank/Public HolidaysPredicted delivery times are based on regular trading days Monday to Friday. Public holidays, bank holidays and weekends are outside the usual scopeof our dispatch and subject to activities/holidays of our carriers and therefore may incur additional days lead time to your order. *UK Mainland (Revised March 2021)

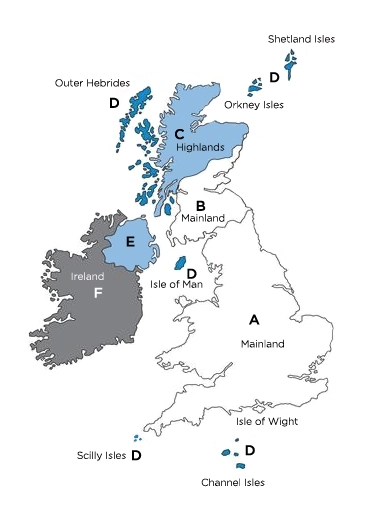

Delivery SurchargesBecause of the high cost of carriage, we regretfully need to apply a surcharge on all deliveries made in the following regions:

Offshore ServicesAll offshore deliveries are a 3-4 day service as standard. This includes Channel Islands, Northern & Southern Ireland, Scottish Islands, Isle of Man and the Scilly Isles. International deliveryInternational delivery charges are automatically added to your order at the checkout. For any questions regarding international deliveries please contact us at sales@isswww.co.uk ExportAll export inquiries should be directed to the export division before placement of order. If no shipping option is available to your selected country please call us FREE on 0800 0224 060 to discuss your requirements.

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||